Refrigeration System Working

Refrigeration System Working

Refrigeration Working System

Refrigerators are used in businesses and homes for one reason: to keep food cold. Refrigerators are essential because they keep food fresh for longer, reducing food waste in both homes and businesses. They help companies preserve food quality for longer and increase revenue by giving chefs the time and opportunity to create their best dishes.

World Refrigeration Day was established in 2019 to raise awareness among the international community about the importance of HVAC-R in society. For millennia, mankind has depended entirely on nature to supply ice.

From the underground food and beverage storage structures built with terracotta rings by the Chinese emperor Shih Huang Ti (220 B.C.) to the ice farms along the Hudson River in the mid-nineteenth century, the development of refrigeration technology was hampered by natural scarcity. ice during the winter months (Gantz, 2015).

Introduction: (Refrigeration System Working)

Refrigeration systems in the chemical industry are often made of standard equipment that can be used in a variety of industries. Because of factors such as temperature range requirements, power demands, fluctuating loads, hazardous locations, and the presence of corrosive chemicals, the chemical industry requires designs and efficiencies that differ from commercial facilities.

Systems are typically designed by specialists, with process engineers providing the design requirements.

A few Basic Definitions of Refrigeration systems

1. Heat is a form of energy that is transferred as a result of a temperature difference. To a greater or lesser extent, heat occurs everywhere. It cannot be created or destroyed as a source of energy, although it can be converted from one form of energy to another. It is important to note that heat energy moves in only one direction: from a warmer object, material, or region to a cooler one.

2. The absence of heat in an object, liquid or region is called cold. No method has yet been developed to achieve "absolute zero," the state in which all heat is extracted from an entity, material, or region according to another concept. On a Fahrenheit thermometer scale, this zero point would be 459.69 degrees below zero, or 273.16 degrees below zero on a Celsius thermometer scale.

3. Refrigeration, also known as cooling, is the process of removing excess heat from one object, material, or place and transferring it to another. The temperature can be reduced by using ice, snow, cold water, or mechanical refrigeration to remove heat.

4. The use of mechanical elements arranged in a "refrigerator" for the purpose of transmitting heat is known as mechanical refrigeration.

5. Refrigerants are chemical compounds that are compacted and condensed into liquids and allowed to cycle through mechanical refrigeration systems into vapors or gases.

The refrigeration cycle is based on the well-known physical theory that when a liquid expands into a gas, heat is extracted from the surrounding material or area. (You should test this idea by wetting your finger and holding it up to the light.) It cools down faster than the others, especially when exposed to any air movement.

This is because the liquid you've dipped it in is evaporating, drawing heat from the skin of the finger and the air around it).

Refrigeration Stages (Refrigeration System Working)

Many implementations have successfully used refrigeration systems with one, two, three or four stages of compression. The number of refrigeration stages is determined by the number of compression stages required, the economy and the compression form. The phases are illustrated in the following sections.

One-Stage Methodology

A typical one-stage refrigeration device for pure propane refrigerant is shown below. It illustrates a single-layer chiller in use and the cooling curve that goes with it

Two-stage Methodology

A two-stage refrigeration device with an interstage flash economizer is commonly used to save money. Process heat can be removed at the interstage level instead of the lower stage level to save even more money.

Three-Stage Methodology

Flash economization and an intermediate heat source can be used similarly as in a two-stage system. Even if the savings aren't as obvious as a two-stage system versus one-stage, they can still be significant enough to warrant additional equipment.

If the number of stages is increased, the energy consumption can be reduced.

As the number of stages increases, the cost of building the refrigeration device increases and the optimal total cost is calculated by the specific system, which is chosen based on a collection of economic criteria. Refrigeration compression horsepower can be further reduced by shifting the refrigerant load from cold to warm temperatures.

With 25°F propane, the gas is first cooled to 30°F, then to 35°F with 40°F propane. A temperature of 25°F was chosen. With 25°F propane, the gas is first cooled to 30°F, then to 35°F with 40°F propane. The 25°F stage was chosen because the compression ratio of each stage was identical. Equipment or process conditions can control the interphase pressure and associated refrigerant temperature.

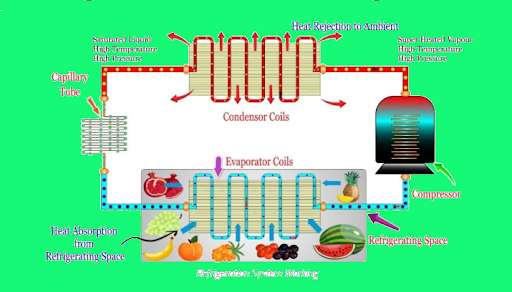

How a Refrigeration System Works

Most refrigerators work on the principle of vapor compression. The compressor, condenser, expansion unit and evaporator are the four essential components of a modern refrigeration system. A volatile liquid (refrigerant liquid) circulates through the refrigeration system, where it is regularly converted into liquid and vapor forms.

Compressor works to compress superheated vapor from low pressure (evaporation pressure) to high pressure (condensation pressure). Next, the high-pressure, high-temperature refrigerant flows into the condenser.

The mechanical components of a conventional refrigerator make it easy to reach and maintain cold temperatures. These are the parts that keep the refrigeration cycle running. To achieve the desired results, these ingredients are highly specialized. These include a compressor, condenser, expansion valve/metering or throttling unit and evaporator.

Also, refrigerators must use a refrigerant, which is a liquid that provides cooling. Refrigerant is required to move through all of these components and refrigerant must be exchanged in each to achieve the required temperature.

Refrigeration System Components

Compressor

Its function is to control a motor and a pump to control the flow of refrigerant. This will then pressurize the refrigerant and consequently reduce its volume.

In both industrial and domestic refrigerators, there are five different types of compressors. Reciprocating, rotary, pin, centrifugal and scroll are some of them. Reciprocating compressors are the most common form of compressor used in home and commercial kitchen refrigerators.

Condenser

The refrigerant is condensed by the condenser. The refrigerant is then cooled by turning it into a liquid in the condenser.

Condensers are divided into three categories.

In the room. They are suitable for small amounts of refrigerant. Since there is an aluminum or copper coil behind the refrigerator, air-cooled condensers are also called coil condensers. The coil increases the surface area of the refrigerant for cooling.

There are two types of air-cooled condensers. A natural convection condenser is a device that uses the natural flow of air to condense a liquid

Cold wind. There are two types of air-cooled condensers. Forced convection condenser uses a fan to draw in cold air and natural convection condenser uses the natural flow of air to cool the refrigerant.

Condenser that is cooled by water. They are used in large plants with a lot of refrigerant. The cooling effect on the refrigerant is provided by water. Water-cooled refrigerants are classified into three categories.

Water-cooled condenser. Water-cooled system which is tube-in-tube or double pipe type shell and coil type shell and tube type water-cooled system which is tube-in-tube or double pipe type water-cooled system which is tube-in-tube.

Evaporative condenser is a form of evaporative condenser. They are a mix of water-cooled and air-cooled compressors used in ice plants.

Evaporative condenser is a form of evaporative condenser. They are a combination of water-cooled and air-cooled condensers used in ice plants. As a result, they have advantages over all types of condensers.

Evaporator

Inside the refrigerator, the evaporator absorbs heat. It acts as a heat transfer medium between the stored product (load) and the refrigerant. The evaporator is usually the coldest component of a fridge or freezer. The refrigerant travels slowly to cool and absorb as much heat as possible from the load. As it absorbs the sun, it heats up and turns into a gas.

More heat is removed from the load as the refrigerant evaporates. The refrigerant is then forced back to the pump, now hot and gaseous.

Refrigeration Models (Refrigeration System Working)

Refrigeration heat loads are linked to compressor energy in refrigeration system models. The compressor sections of the refrigeration model use the same basic equations as the compressor models discussed earlier. The refrigeration system should use the correct composition and any makeup gas will have a component mixture.

The overall refrigeration load is determined using the estimated compressor suction flow and the heat exchange rate calculated by the individual unit model. The enthalpy difference between each refrigerant layer is used to measure the refrigerant vapor flow produced by this load. Compressor discharge is predicted using the exchanger model of the refrigerant condenser.

Refrigeration system Thermodynamics

Refrigeration systems work by repeating a series of thermodynamic processes to return the working material to its original state. A thermodynamic refrigeration cycle (freezing) extracts heat from a low-temperature object and rejects it at a higher temperature. This cyclic process requires work feedback to avoid violating the second law of thermodynamics

The reverse Carnot cycle is the basis of ideal refrigeration devices. The Carnot cycle is a theoretical term because it is ideal, meaning it is lossless, frictionless and has no temperature variation in the heat exchange process. None of these ideas will ever materialize.

The reverse Carnot cycle is the basis of ideal refrigeration devices. The Carnot cycle is a theoretical term because it is ideal, meaning it is lossless, frictionless and has no temperature variation in the heat exchange process. In fact, none of these ideals will ever materialize. Consequently, the Carnot cycle serves as a benchmark against which the output of all other refrigeration cycles can be measured.

Understanding the Refrigeration System

The refrigeration cycle involves the transfer of refrigerant from one location to another with the ultimate goal of lowering the temperature of a cabinet, counter, or cold storage. One of the most important reasons to learn how your commercial refrigerator works is so you can easily clean and repair it.

No comments